CLAL

Market

Tools

- Overview

- Prices

- Production

- Per capita Consumption

- In depth

- WORLD: Milk Production Map

- WORLD: Mozzarella Export

- RCEP: Producers and Exporters

- EU: milk self-sufficiency rate

- EU: Fat & Protein

- FARM S/STEM Project

- Simulators

- Grana Padano Payout

- EU: Payout SMP + BUTTER

- USA: Payout NDM + BUTTER

- NZ: Payout SMP + BUTTER

- NZ and EU: Payout WMP + BUTTER

- INDIA: Payout SMP + BUTTER

- Prices & Exchange Rates

- Commodities and Currency

-

Crude Oil & GAS

- export to OPEC

- import of Crude Oil producers

- import of natural GAS producers - Exchange rates

- GDP

- CPI

- Palm Oil

- Futures

- Customs duties

- Energy and raw materials costs

- Climatic phenomena

Dairy by Country

- Oceania

- · Australia

- · New Zealand

- Middle-East

- · Turkey

- EUROPE

- European Union

- ITALY

- Dairy Economics

Topics

Newsopen

WORLD

- Milk production and Export in Milk Equivalent of the main exporting countries

- US: Price of Processed Cheese

- RCEP: Milk Producers and Exporters

- USA: Payout NDM + Butter

- New Zealand: Payout SMP + Butter

- Exports Spotlight

- Turkey: 'Recommended' prices of farm-gate raw milk

EUROPE

- Milkfat supply

of which: Germany, France, Netherlands, Poland, Belgium, Ireland - Milk protein supply

of which: Germany, France, Netherlands, Poland, Belgium, Ireland - Whole Milk Powder (WMP), France

- German Länder: Monthly Milk Deliveries and Dairy Cows

- Regions of France: Monthly Milk Deliveries

- Great Britain and Northern Ireland: Milk Deliveries

ITALY

Economic Advantage Analysis Area open

Milk Areaopen

WORLD

- Milk overview

- Milk Production / Deliveries Map

- Monthly Milk Supply

- EU-NZ: Production season overview

- Comparison between Milk Deliveries and Population

- Comparison of the Milk price at farmgate:

Cheese Areaopen

WORLD and EUROPE

- Cheese overview

- SLICED / Asiago wholesale prices

- Cheese wholesale price

- Edamer wholesale price

- Edamer, SMP and Farm-gate price (Bavaria)

- EU-27: Cheese from cow's milk production

ITALY

- Grana Padano & Parmigiano Reggiano prices/production

-

Comparison wholesale prices / production

Butter Areaopen

WORLD

EUROPE

Powder Areaopen

WORLD

EUROPE

-

Milk protein supply

of which: Germany, France, Netherlands, Poland, Belgium, Ireland - Whey powder for animal feed prices

- SMP production

- WMP production

ITALY

Stocks Areaopen

WORLD

- USA-EU: Butter Stocks

- USA-EU: SMP Stocks

- USA - Cheese Stocks

- USA - WPC Stocks and Prices

- USA - Dry Whey Stocks and Prices

- USA - Lactose Stocks, Production and Prices

EUROPE

-

EU-27 BUTTER: Production + Import - Export

of which: Germany, France, The Netherlands, Poland -

EU-27 Skimmed Milk Powder (SMP): Production + Import - Export

of which: Germany, France, The Netherlands, Poland -

EU-27 CHEESE: Production + Import - Export

of which: Germany, France, The Netherlands, Poland

Animal Health Areaopen

Livestock Feeding and Mineral Fertilizers Areaopen

WORLD

- Comparison among Corn, Soybeans and Wheat prices in the USA

- Comparison among Corn, SMP and Crude Oil prices in the USA

ITALY

-

Feeder Cattle Prices

- Cereals and by-products (Soft wheat, Hard wheat, Italian corn, EU barley, Bran, Sorghum)

- Fodder and by-products (Pressed lucerne hay, Pressed first crop hay, Dehydrated lucerne in bales)

- Fodder and by-products (Pressed straw, Beet molasses, Dried pulps)

- Oilseeds and by-products (Italian soybeans, Foreign soybeans, Linseed cake, Italian soybean meal, Foreign soybean meal, Italian decorticated soybean meal, Foreign decorticated soybean meal, Sunflower wholemeal, Decorticated sunflower meal, Rapeseed meal)

- Milk:Feed Ratio - milk price divided by feed cost

Import-Export Areaopen

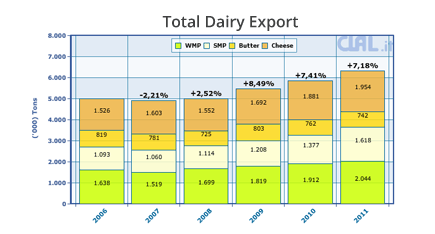

Dairy world trade

CLAL.it outlines the import and export trade flows of Cheese, Butter and AMF, Milk Powders, Whey and WPC, Condensed Milk, Packed and Bulk Milk, Lactose, Casein and Caseinates by the main international players.

enter

enter

Slideshow

CLAL.it provides with some training paths, updated in real-time and useful to market analysis during workshops and project works.

enter

enter

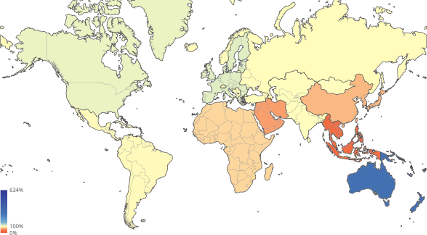

Milk Atlas

CLAL.it provides with a snapshot of the Milk production and livestock (cow, buffalo, goat, sheep, camel) and a number of interactive maps that visualize Milk Self-sufficiency worldwide.

enter

enter

Services

- Consulting

- Market Analysis

- Training

- FARM S/STEM Project

- Multimedia

- Videoclip

- Photo Galleries

subscribe

subscribe

CLAL News is an information service on the national and international dairy market, developed by the CLAL Team and Leo Bertozzi.

The information is addressed to all operators in the sector and concerns the market, product innovation, the strategies of the major companies and retailers.

On the right you can find the latest news in English language.

CLAL News is mobile-friendly: use the QR code to access from your smartphone

Cheeses lead the recovery of US exports

Authors: Mirco De Vincenzi, Elisa Donegatti, Ester Venturelli Clal.it – Monthly variations of exported quantities of dairy products ... read

Rice: India faces climate effects

By: Elisa Donegatti and Ester Venturelli India is the second world producer of Rice, following China, with 132 Mio Ton in the 2023-24 ... read

Corn and Soybean: the race between the US and Brazil

By: Ester Venturelli and Elisa Donegatti For years Corn and Soy global export has been mainly led by two countries: the US and Brazil. The ... read

India turns to import to reply at dairy demand

Di: Ester Venturelli CLAL.it – India: Import and Export trends of dairy products India is the main milk producer in the world. ... read

Market News World

| In calo | Malaysia: Palm oil price | -3,90% |

| In aumento | Mexico: Milk Production | +2,38% |

| In aumento | Uruguay: Farm gate milk price | +4,45% |

| In calo | Uruguay: Milk Delivery | -7,12% |

| In calo | US: Cow's milk production | -1,05% |

| In calo | Argentina: Milk delivery | -14,35% |

| In calo | New Zealand: Milk Production | -3,47% |

| In aumento | US: Cheese 40# Blocks price | +9,45% |

Market News Europe

| In aumento | Netherlands: Skim Milk Powder feed price | +0,45% |

| In calo | Netherlands: Butter price (82%) | -2,17% |

| In aumento | France: Butter price (82%) | +0,14% |

| In calo | France: SMP price (Poudre 0%) | -0,50% |

| In aumento | Germany: Whole Milk Powder (WMP) price | +1,37% |

| In calo | DE, Kempten: "Markenbutter" price | -1,67% |

| In aumento | Austria: Farm gate milk price | +0,90% |

| In calo | Romania: Farm gate milk price | -0,90% |

Market News Italy

| In calo | IT, Verona: foreign Whole Spot Milk price | -4,65% |

| In calo | IT, Verona: Spot milk price | -2,22% |

| In calo | IT, Verona: foreign Skim Spot Milk price | -17,65% |

| In calo | IT, Milan: Spot milk price | -2,25% |

| In calo | IT, Milan: Spot Milk price from France | -4,76% |

| In calo | IT, Milan: Spot Milk price from Germany | -4,60% |

| In calo | IT, Milan: foreign Spot Milk 0,03% price | -15,63% |

| In calo | IT, Milan: Raw "spot" Organic milk price | -0,88% |

Explore CLAL.it

Dairy Market

- Italy

- Milk

- Cheese

- Butter

- Whey and by-products

Comparison Graphs

- Milk

- Cheese

- Milk Powders and Whey

- Butter

- Commodities and currency

- Crude Oil

- Exchange rates

- GDP

- CPI

- Palm Oil

Dairy by Country

- World

- North America

- · USA

- South America

- · Argentina

- · Brazil

- · Chile

- · Uruguay

- East Asia

- · China

- · Japan

- South Asia

- · India

- · Pakistan

- Oceania

- · Australia

- · New Zealand

- Middle East

- · Turkey

- Europe

- · EU-27

CLAL.it

- Research & Analysis

- Dairy World Trade

- Slideshows

- Exports Spotlight

.jpg)

.jpg)